Wastewater treatment in the food industry

Wastewater from the food industry may be very diverse in its composition. Often ingredients such as sugar, protein, fat or oil generate high COD values and hence high cost of disposal. Economic benefits such as avoiding the surplus charge can be achieved by internal wastewater (pre)treatment. Also, a direct disposal is possible with simple technologies. In some cases, preliminary stages, such as a flotation or sedimentation, are necessary depending on the industry. For example a flotation is a proven way for a separation of floating fats and oils, as well as suspended solids in the fat or oil processing industry.

For accurate data collection, small, compact pilot plants can be temporarily installed on-site to make a perfect design of the plant possible. Depending on the application, ACS Environmental is able to offer the suitable type of reactor.

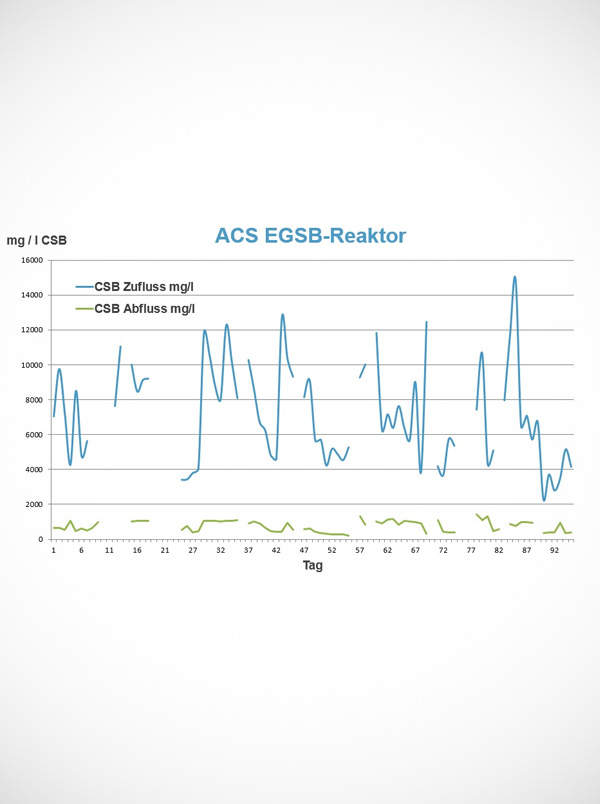

The ACS EGSB reactor with its patented technology reduces the COD loads by 85-90% and reduces the BOD5 concentration by 90%. The ACS UASB reactor benefits even in low amounts of wastewater, especially for smaller manufacturers. The ACS Lipothan reactor is always recommended when fats, oils or proteins are present in small amounts. A circulation in the reactor takes place until a complete degradation has occurred. A flotation can then be dispensed.

Examples:

Confectioners, bakeries, fisheries, industrial mills, dairies, starch, meat product, mustard, sugar and tobacco manufacturers.

Suitable reactor:

Example pant

Thüringer Fish Delicatessen Gebr.Hopf

| Substrate | wastewater from production |

| Calculated for | 40 m³/d, 500 kg COD/d |

| Location | Floh-Seligenthal, Germany |

| Similar references | Rügen Fisch AG, Unilever UK Ltd, DSF, Lausitzer Früchte, |